AIR CONDITIONING REFRIGERANT LEAK TESTING & REPAIRS

CHECKING THE FGAS LOG BOOK

Before completing FGas refrigerant leak testing, qualified FGas Engineers need to check the Refrigeration, Air Conditioning & Heat Pump (RACHP) equipment FGas Log Book records.

These FGas Log Books should indicate the FGas charge in CO2 Equivalent.

Special attention should be paid to relevant information indicating any recurring issues and problem areas.

Contact us today to help with your next FGas Refrigerant Compliance contract review project, keeping your Air Conditioning systems working throughout Weybridge, Surrey, Sussex, London and Kent.

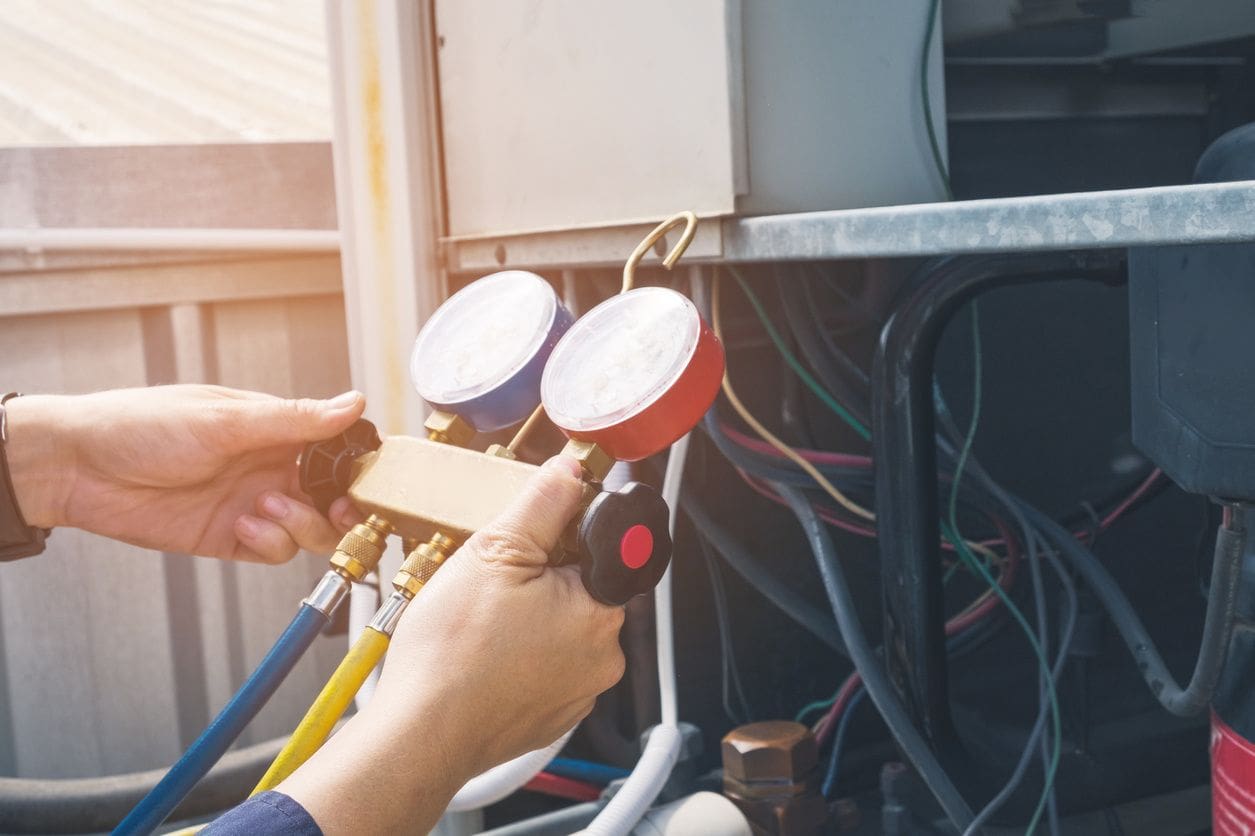

SELECTION OF AIR CONDITIONING REFRIGERANT LEAK TESTING METHOD

Particular characteristics of the Refrigeration, Air Conditioning & Heat Pump installation need to be taken into consideration when selecting the appropriate refrigerant leak testing method e.g. ventilation of the environment, etc.

Indirect Measuring Methods are only applied where the parameters analysed can be expected to give reliable information on the charge and the likelihood of leaks.

Direct Measuring Methods can always be applied and are necessary to identify the exact location of the leaks.

CHECKING FOR AIR CONDITIONING LEAKS USING THE INDIRECT OR DIRECT METHOD

The following equipment parts should then be systematically checked:

- Joints, valves (including stems)

- Seals (including seals on replaceable driers and filters)

- Any parts of the system subject to vibration

- Connections to safety or operational devices

Indirect Measuring Methods Include

- visual and manual checks of equipment parts, safety and operational devices, combined with analysis of one or more of the following parameters: pressure, temperature, compressor current, liquid levels, recharge volumes

Any presumption of leakage from the Indirect Measuring Method should then be followed by the application of a Direct Measuring Method for further examination and identification of the location of the leak.

When the above mentioned parts of the equipment show no signs of leakage but a leak is suspected, other parts of the system should also be checked.

Example presumption of FGas refrigerant leakage includes the following items:

- A fixed leakage detection system indicates leakage

- The Refrigeration, Air Conditioning & Heat Pump (RACHP) equipment produces abnormal noises, vibration, ice formation or insufficient cooling capacity

- Indications of corrosion, oil leaks and component or material damage at possible leakage points

- Indications of leakage from sight glasses, level indicators or other visual aids

- Indications of damage in safety switches, pressure switches, gauges and sensor connections

- Deviations from normal operational conditions indicated by the parameters analysed, including readings from real time electronic systems

- Other signs indicating refrigerant charge loss

Direct Measuring Methods Include

- Checks using our FGas Refrigerant gas detection devices adapted to the refrigerant with a sensitivity of at least 5 g/year

- Checks using proprietary bubble solutions / soapsuds

- Checks using the application of UV detection fluid (or suitable dye) in the circuit (only if approved by the manufacture)

Before pressure testing with a suitable pressure testing gas (e.g. Oxygen-Free-Nitrogen), the refrigerant should be recovered from the whole system by suitably qualified FGas Engineers.

REPAIRING OF AIR CONDITIONING REFRIGERANT LEAKS

Repairing FGas Refrigerant Leaks on Refrigeration, Air Conditioning & Heat Pump (RACHP) equipment is an important legal requirement that carries fines of up to £200,000 within the UK and detected leaks must be repaired as soon as possible.

Where necessary, the repair should be preceded by a pump-down or recovery of the FGas refrigerant and followed by a leakage test with Oxygen-Free-Nitrogen or other suitable pressure testing and drying gas, repaired, evacuated, recharged with FGas refrigerant and leak tested.

After the repair, the Refrigeration, Air Conditioning & Heat Pump (RACHP) equipment FGas Log Book records should be updated with the relevant information and the cause of the leak identified as far as possible to avoid recurrence.

REFRIGERANT LEAKS FOLLOW-UP CHECK

After Refrigeration, Air Conditioning & Heat Pump FGas refrigerant leaks are repaired, a follow-up leak check needs to be carried out within one month, following the aforementioned requirements.

Special consideration should be given to areas where leaks had previously been found, repaired and in adjacent areas where stress was applied during the repair while following the requirements of a standard FGas Refrigerant leak check.

UPDATING FGAS REFRIGERANT LOG BOOK RECORDS

Refrigeration, Air Conditioning & Heat Pump (RACHP) Equipment records should always be updated following each FGas Refrigerant leak check, and a review completed with the building owner highlighting any further recommendations.

Contact us today for assistance with your next FGas Refrigerant Compliance contract review project to keep your Air Conditioning systems working throughout London, Surrey, Sussex and Kent.